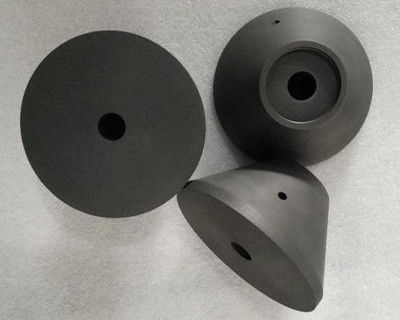

Dry Running Graphite Bearings

Dry Running Graphite Bearings,Outstanding dry-running properties High thermal resistance High resilience

For dry-running slide bearing applications, such as in furnace systems, our graphite materials are characterized primarily by their outstanding dry-running and sliding properties, as well as their high thermal resilience. Their low friction coefficient, paired with a wide variety of counter-rotation materials, is a big advantage.

Material Technical Specifications:

| Type |

Max Grain size mm |

Bulk Density g/cc |

Specific resistivity μΩ.m |

Flexural Strength Mpa |

Compressive Strength Mpa |

C.T.E(100-600℃)

x10-6/℃ |

Ash % |

| ZGB-I |

0.8 |

≥1.68 |

≤9.5 |

≥13.0 |

≥28.0 |

≤2.8 |

≤0.3 |

| ZGB-II |

0.58 |

≥1.72 |

≤8.5 |

≥15.0 |

≥32.0 |

≤2.4 |

≤0.3 |

| ZGL-0 |

2 |

≥1.58 |

≤11.5 |

≥7.0 |

≥18.0 |

≤3.0 |

≤0.3 |

| ZGL-I |

2 |

≥1.68 |

≤9.0 |

≥13.0 |

≥28.0 |

≤2.7 |

≤0.3 |

| ZGDJY-C1 |

22 |

≥1.78 |

≤10 |

≥38.0 |

≥65.0 |

≤3.9 |

≤0.07(Normal)

≤0.005(Purified) |

| ZGDJY-Y3 |

22 |

≥1.86 |

≤13.0 |

≥40.0 |

≥80.0 |

≤3.9 |

≤0.07(Normal)

≤0.005(Purified) |

| ZGDJY-W5 |

22 |

≥1.85 |

≤12.0 |

≥45.0 |

≥90.0 |

≤4.3 |

≤0.07(Normal)

≤0.005(Purified) |

| MY-III |

45 |

≥1.83 |

≤10.0 |

≥38.0 |

≥80.0 |

≤3.5 |

≤0.1 |

| MY-IV |

45 |

≥1.88 |

≤9.0 |

≥42.0 |

≥90.0 |

≤3.8 |

≤0.07 |

| If you can not find the material which you need, please kindly contact us ,we will choose apporpiate materialaccording to customer's application (working condition)based on rich experiences in graphite application |

You benefit from these advantages:

Features:

-

Excellent thermal durability

-

Good thermal conductivity

-

Resists wetting by molten metals

-

Complex shapes can be processed

-

Reduces metal sleeve weight

-

Various surface modifications and treatments enable a variety of applications

Due to its ability to resist wetting by molten metals, graphite is used as a mold material for strip dies, tubular dies, and other molds used in continuous casting processes for copper and copper alloys (brass, bronze, and nickel silver), aluminum alloys, cast iron, precious metals, and a variety of other metals.

Graphite can be used with different continuous casting methods (horizontal/vertical) and can be produced in a variety of ingot shapes (including plates, strips, pipes, rods, wire, and contoured shapes).

With a wide range of grades available, we can select the optimal grade for a variety of cast metals and alloys.

We manufactures products from structural brands of graphite, impregnated graphite, antifriction graphite

Graphite has unique properties:

-

electrical conductivity;

-

heat resistance (sublimation effect);

-

poor wettability by many metals;

-

strength, anomalously increasing with temperature increasing;

-

possibility to work with dry friction (self-lubrication)

Due to its unique properties, graphite products are used in many industries:

-

production of ferrous, non-ferrous and precious metals;

-

engineering;

-

chemistry, petrochemistry and oil refining;

-

glass industry;

-

analytical laboratories;

-

power engineering and electrical engineering.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!