Advantages of ZrO2 stirrers compared with other ceramic stirrers:

- Better stirring action thanks to unlimited design possibilities

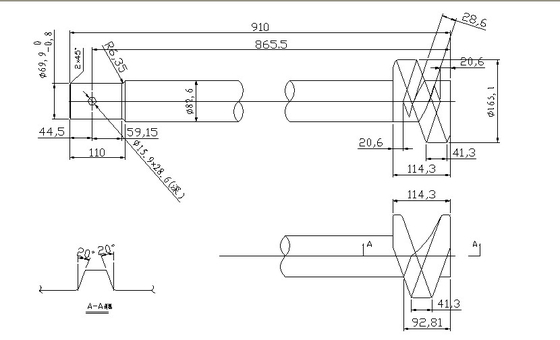

- Small shaft diameter and large blade diameter for more effective stirring

- Higher mechanical stability

- Better thermal shock resistance

- No contamination of the glass melt

- Considerably longer service life

We have stock for alumina (Al2O3) and make under request, in the following materials:

- magnesia partially stabilized zirconia (Mg-PSZ),

- yttria-stabilized tetragonal zirconia (Y-TZP) zirconia

- partially stabilized with yttria (Y-PSZ),

- zirconia fully stabilized with yttria (Y-FSZ),

- zircon (ZrSiO2),

- aluminum titanate (Al2TiO5),

- mullite (Al6Si2O13)