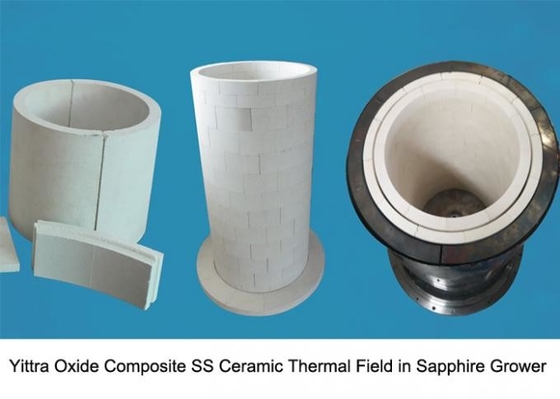

Product Introduction

Raw material of rare-earth composit oxide solid solution ceramic thermal shield designed and producing by ZG selected standardization,technological process,after melt under 2850 deg.cel., formed stable solid solution transparent large crystals,crush into grain, powder, instantly blow the bubble hermetic thermal isolation ball by using high pressure airflow, the whole process of combined program from raw material, technology, to second time combined sintering products and application, have laid the basic advantage for super high-temp. artificial crystal thermal field system Fangming Newm produced.

Obvious advantages of Thermal Field

1. Can directly act on heater radiation.Applied in above 100-120kg grade KY method big-size crystal Grower, the excellent comprehensive performance has been reflected.Solid Solution Ceramics is super low thermal conductivity material, as super low thermal conductivity matched high reflecting rate of metal screen, can further improve the accuracy of thermal field control and temperature gradient, meantime improve the crystal growth yield, bring down power consumption, bring down the metal thermal field invest and working cost.

2. As ZrO2 thermal shield in crystal grower, it is the best working effect, many times repeatedly working and working life reached 3 years recycle period in crystal grower a present, shorten 25% of the crystal growth period, bring down 40% of energy consumption, have the one time oxygen release and do not store oxygen, 0 release, do not corrode melt parts in the furnace, the only Rare-Earth Composite Oxide Solid Solution Ceramic Thermal Field .

3. It is one kind of recyclable material, recyclable material can be secondly used in producing ceramics in other high-temp. industry through special process, is one kind of green, eco-friendly, energy-saving, down-consumption in the whole production process, and recycling resources ecological chain product.

Vacuum environment and after deoxidation condition

Rare-Earth Composite Oxide Solid Solution Ceramic Material works for 24 hours in 2300 deg.cel. vacuum environment and after deoxidation. No size changes, no volatilization, no expansion or shrinkage, in 2300 deg.cel. environment,no agglomeration or melting,no deformation or crack, etc. problems appear. The oxygen contained in material has been released completely, and in heating in room air or vacuum environment,not any oxygen absorption behavior occurs.

The quality of products we are producing is the same, even better than the one produced by the other producers in the same industry from USA, European countries.

![]()