Waterjet Cutting Abrasive

Basic information

SINOGARNET® is a natural mineral waterjet cutting abrasive. The main component is almandite garnet, one of the hardest minerals. We closely cooperate with the leading waterjet equipment manufacturers to develop the higher performance and more cost-effective products for the customers. We remain the garnet leading supplier in China who keep product research, development, performance and cost-effectiveness.

Up to now, we produces a wide family of waterjet abrasives to meet various waterjet cutting applications.

SINOGARNET® Advantages in Waterjet Cutting

Garnet comes in two basic forms, crushed and alluvial, the later being roughly similar to sand washed up on riversides. Our garnet for export is produced from our crystalline almandite garnet deposits. Thank to its sharp edges from crushing, this kind crushed garnet acts more like a sharp cutting tools so that it is superior to alluvial and have been shown to cut better and faster.

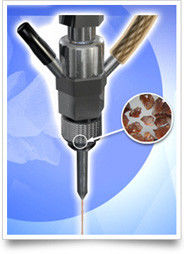

Sharper Edges - Due to our SINOGARNET® is crushed from almandine rock, it acts more like a sharp cutting tools and can cut faster and more efficiently than alluvial garnet.

Faster Cutting - Crushed and selected from hard rock so that SINOGARNET® waterjet grade garnet produces harder and sharper edges than other waterjet abrasives. These characteristics enable our garnet more like a hard and sharp cutting tool to finish a faster cutting.

Better Edge quality - According to the cutting material and edge quality requirement, there are various special and proper waterjet grades recommended that enable a better edge quality.

Less Dusty - SINOGARNET® garnet has high garnet purity and very low dust. That makes the whole cutting course more smoothly.

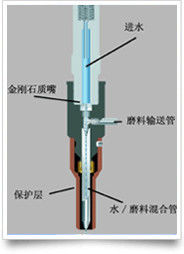

Choosing the Proper Mesh or Grade

SINOGARNET® offers various grades to match any focusing tube and orifice for any given cutting applications. Choosing the proper mesh, or grade, for the operation is very imperative. Different mesh sizes of garnet are designed to pass through different sized nozzles and choosing the wrong grade could be stop a waterjet operation completely. If the garnet grade is too large or coarse, the granules can jam inside a tube and cause a blockage. Too fine an abrasive have a tendency to “clump” together inside the cutting head and again, have the potential to clog. Or it may inhibit the flow of garnet in the feed tube and not consistently enter the venture of water flow between the jewel and nozzle. If you are not sure which mesh or grade is proper, feel free to Contact Us and we would like to give you our professional suggestions.

|

Characteristics

|

|

Shape

|

Angular

|

|

Specific Gravity

|

4.0 – 4.2

|

|

Bulk Density

|

2.0 – 2.3

|

|

Moh Hardness

|

7.0 – 8.0

|

|

Acid Solubility

|

Insoluble

|

|

Typical Chemical Analysis

|

|

SiO2

|

33-37%

|

|

Al2O3

|

17-21%

|

|

MgO

|

4-6%

|

|

FeO+Fe2O3

|

33-42%

|

|

CaO

|

1.5-2%

|

|

MnO

|

0-1.5%

|

|

TiO2

|

0-1.5%

|

|

Standard Mesh Sizes

|

Coarse 60 Mesh

Medium 80 Mesh

Fine 120 Mesh

More fine grades 150 mesh, 180 mesh, 200 mesh, 220 mesh

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!