AlN Metalization (HTCC)

Aluminum nitride(High Temperature Co-Fired Ceramic) is a kind of ceramic substrate with high thermal conductivity and high density,

whichis made by pre-designed circuit through punching,filling andprinting onthe AlN green type, and then laminated and sintered

at high temperature.

Advantage:

● First company with commercial AIN HTCC mass production capacity in China

● Independent R&D and manufacturing of core equipment: hightemperature refractory metalfurnace

● Master the special formula of AIN green tape for HTCCMaster the special formula of tungsten slurry for HTCC

● Design and development capabilities with HTCC products

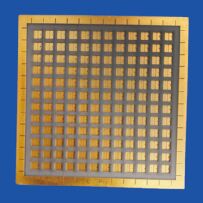

Overall technical indicators:

·Specification ofgreen tape:6” *6"

·thickness:120-200um

Minimum Linewidth of HTCC Printing:10Oum

Minimum spacing ofHTCC printing:100um

· HTCC Conductor Printing Thickness:7-20um

Minimum through-hole diameter:100um

. Warpage:<3um/mm

·HTCCLayers:3-30

· Shrinkage ofraw porcelain sheets

17%in thedirection ofXY axis;

· In the direction of Z axis 19土3%

·Square resistance:21.6Ω

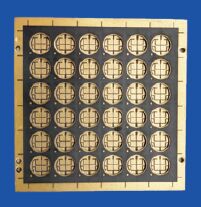

Production application:

Our products are currently mainly used in LED packaging, microelectronics and semiconductors, automotive electronics, high-power power electronic modules, RF microwave communications, aerospace, and other fields.

Aluminum nitride not only can withstand high temperatures, corrosion, and the erosion of alloys and metals such as aluminum and iron, but it is also non-wetting to silver, copper, aluminum, lead, and other metals. Therefore, it can be used to make coatings for refractory materials or crucibles as surface protection materials. Additionally, it can be made into casting molds and crucibles and other structural materials. Nano aluminum nitride can be used as a dispersed phase in structural materials to enhance the thermal conductivity, rigidity, and strength of the matrix material. For example, aluminum nitride can be used to improve the rigidity and strength of certain metals, and it does not react with the metals at processing temperatures, which allows composites more time to form in the molten state and better control the interface between the matrix and the filler. Aluminum nitride is also used to improve the thermal conductivity and rigidity of polymer materials, reducing their thermal expansion. Studies have found that adding nano aluminum nitride to coarse and fine aluminum nitride powders can effectively improve the density and thermal fatigue resistance of aluminum nitride ceramics. Adding heat-treated nano aluminum nitride powders to corundum-spinel castables can enhance their erosion resistance.

With the development of the electronics industry, especially microelectronics technology, aluminum nitride ceramic materials are highly suitable for use as semiconductor substrates due to their excellent properties in thermal conductivity, insulation, dielectric characteristics, matching thermal expansion coefficient with silicon, and strength. They are also the best materials to replace alumina and beryllia substrate materials. Especially in the production of very-large-scale integrated circuits, as chip density continues to increase exponentially, traditional ceramic substrates are increasingly unable to meet the requirements, and aluminum nitride will take on this important role.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!