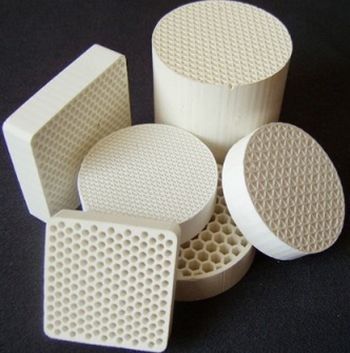

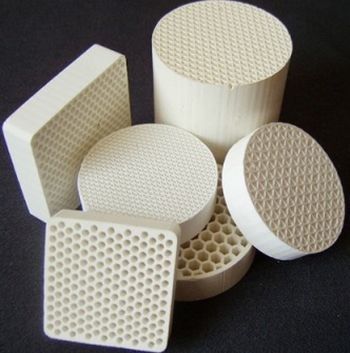

Ceramic catalysts carriers

for purification of gasoline and diesel automobile engines exhaust

A catalyst is a substance that accelerates the course of a chemical reaction without undergoing an irreversible change. Catalysts are important not only for the chemical industry, but also for solving environmental problems.

Ceramic structures with a high specific surface are used as carriers for catalysts. The high specific surface should be preserved after long-term use, as well as geometry and mechanical properties, which implies the carrier’s resistance to thermal and mechanical stresses and to chemical destruction.

Physical and Chemical Properties

| Items |

Unit |

Index |

| Chemical Composition |

SiO2 |

% |

49-51 |

| |

Al2O3 |

% |

33-35 |

| |

MgO |

% |

13-14 |

| Wall Thickness |

mm |

100 CPSI |

0.43 |

| |

|

200 CPSI |

0.32 |

| |

|

300 CPSI |

0.30 |

| |

|

400 CPSI |

0.18 |

| |

|

600 CPSI |

0.15 |

| Crush Strength |

A-axis |

Mpa |

|

≥16 |

| |

B-axis |

Mpa |

|

≥3 |

| Water Absorption |

% |

|

25±2 |

| Coefficient of Thermal Expansion |

10-6/K-1 |

|

0.8-2.0 |

| Maximum Operating Temperature |

°C |

|

≥1370 |

| Bulk Density |

Kg/L |

0.43-0.75

|

Ceramic catalysts carriers are usually used:

-

for purification of gasoline and diesel automobile engines exhaust;

-

for chemical and petroleum refining processes;

-

for cleaning emissions of power plants and other industrial enterprises.

The main requirements for catalyst carriers include a large surface area, heat resistance, porosity, chemical inertness, mechanical strength.

Ceramic and metal carriers compete with each other: ceramics are often more stable and more economical, and therefore dominate in most sectors. Metal is sometimes preferable because of greater mechanical strength and the ability to manufacture catalysts of a certain geometry using wire, foil or thin-wall honeycomb structures.

Product Characteristics

● Large specific surface area: to ensure full access to the exhaust gas with the catalyst.

● Stable water absorption: to ensure the catalyst evenly firmly attached to the surface of the catalyst carrier.

● Warm-up: after start-up the engine, the temperature of the carrier can reach the catalyst activation temperature in the shortest possible time.

● Low exhaust resistance: the engine’s exhaust resistance is small, to ensure that doesn’t affect the engine performance.

● High strength: the operating environment of the catalyst carrier is in the bumpy car, so the catalyst carrier must be high strength without being external damage.

● Good assembly: the carrier is an exhaust assembly parts, only good appearance and precise dimensions can ensure perfect assembly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!